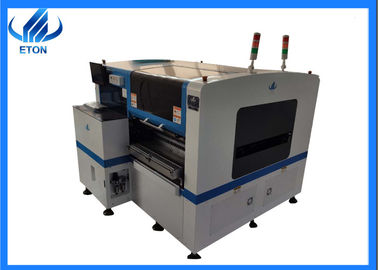

HT-E5D machine is Dual system,dual module multifunctional mounter with high capacity of 80000CPH. It can mount capacitors,resistors,LED3014/3020/3528/5050,IC and shaped components. It applies to power driver,electric board,lens,linear bulb,household appliance and etc.

6.Company profile

Shenzhen ETON automation equipment co., ltd. was established in 2011, which is a high-tech enterprise specializing in the r&d, production, sales and after-sales technical services of SMT high-speed SMT mounter and multifunctional mounter.

As a national brand, ETON automation occupies an absolute leading position in China's LED placement machine industry. At the same time, its products are exported to more than 20 countries, including South Korea, India, Vietnam, Egypt and Turkey.

7.Our clients

8.FAQ

1) Do you have oversea after sale service?

We have set up an overseas office in India.We can offer technical support abroad. If you have any technical problem, our engineers will support you promptly.

2)How is the training?

You can send your engineers to our workshop to study, or we can send our engineers to your workshop for guidance. We guarantee that the training will not be completed until your operators are fully trained.

3) It’s hard to use the machine?

No, not at all. Touch screen display, English operation interface. Generally training about five days can be skilled in the operation of the machine.

4) Does your machines have quality certificates?

We are high-tech enterprise with CE,SIRA,CCC .

5)How about the warranty?

We guarantee it for one year free of charge. Software updates are free for life.

SMT basic process elements include: screen printing (or dispensing), mount (curing), reflow welding, cleaning, testing, rework.

- Screen printing: The function is to seal the solder paste or patch glue to the PCB pad to prepare for the welding of components. Equipment used is screen printing machine (screen printing machine), located at the front end of SMT production line.

- dispensing: it is to drop the glue to the fixed position of the PCB board, and its main function is to fix the components to the PCB board. Equipment used is a dispensing machine, located at the front end of the SMT production line or behind the testing equipment.

- mount: its function is to mount the surface assembled components accurately to the fixed position of the PCB. Equipment used is a placement machine, located in the SMT production line behind the screen printing machine.

- Curing: The function is to melt the patch glue so that the surface assembled components are firmly bonded to the PCB plate. Equipment used is curing furnace, located at the back of the placement machine in the SMT production line.

- reflux welding: its function is to melt the solder paste so that the surface assembled components are firmly bonded to the PCB plate. Equipment used is reflow welding furnace, located in the back of the placement machine in the SMT production line.

- Cleaning: The function is to remove harmful welding residues such as flux from assembled PCB plates. The equipment used is a cleaning machine, the position can not be fixed, can be online or not online.

- Detection: Its function is to test the welding quality and assembly quality of the assembled PCB board. The equipment used is magnifying glass, microscope, on-line tester (ICT), flying needle tester, automatic optical detection (AOI), X-RAY detection system, functional tester, etc. position according to the need of detection, can be configured in the production line where appropriate.

- rework: its function is to detect the failure of the PCB board rework. The tools used are soldering iron, rework workstation, etc. configured in any position in the production line.

contact

Name:Brynn

Email :Brynn@eton-mounter.com

WeChat:13802252825

Telephone:138 0225 2825

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!